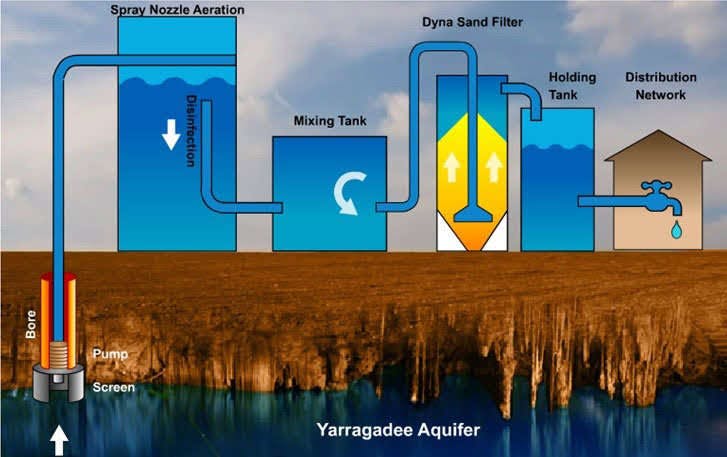

Bunbury's underground water supply is pumped from the Yarragadee Aquifer and contains some iron, manganese and other minerals absorbed from the soil.

When the water is pumped to the surface it is sprayed into the open air via purpose built aerators. This adds oxygen to the water and aids in the removal of iron and manganese.

Chlorine is added to the water to act as a disinfectant against potentially dangerous bacteria. Chlorine is used around the world for water treatment because it is a very effective disinfectant, is economical and provides protection all the way from the treatment plant through to the customer’s tap.

From the aerator, the water is then passed through sand filters, which are large tanks each standing seven metres high. The water is pumped into the bottom of the tank and then it slowly rises through the layers of sand. The sand captures iron, manganese and any other impurities in the water.

The impurities which are trapped in the sand are removed via a continuous backwashing process. Waste water from this process is captured and the impurities allowed to settle out in large settling tanks. The impurities are then concentrated into a product known as sludge. They are dried in sludge drying beds and the waste material taken to landfill.

The filtered water which discharges though the top of the sand is then safe to drink and complies with all of the requirements of the Australian Drinking Water Guidelines. From there it is transported to one of Aqwest’s water reservoirs ready to be delivered to our customers’ taps.